Inkscape supports many advanced SVG features (markers, clones, alpha blending, etc.) and great care is taken in designing a streamlined interface. It is very easy to edit nodes, perform complex path operations, trace bitmaps and much more.

#INKSCAPE GCODE TOOLS FREE#

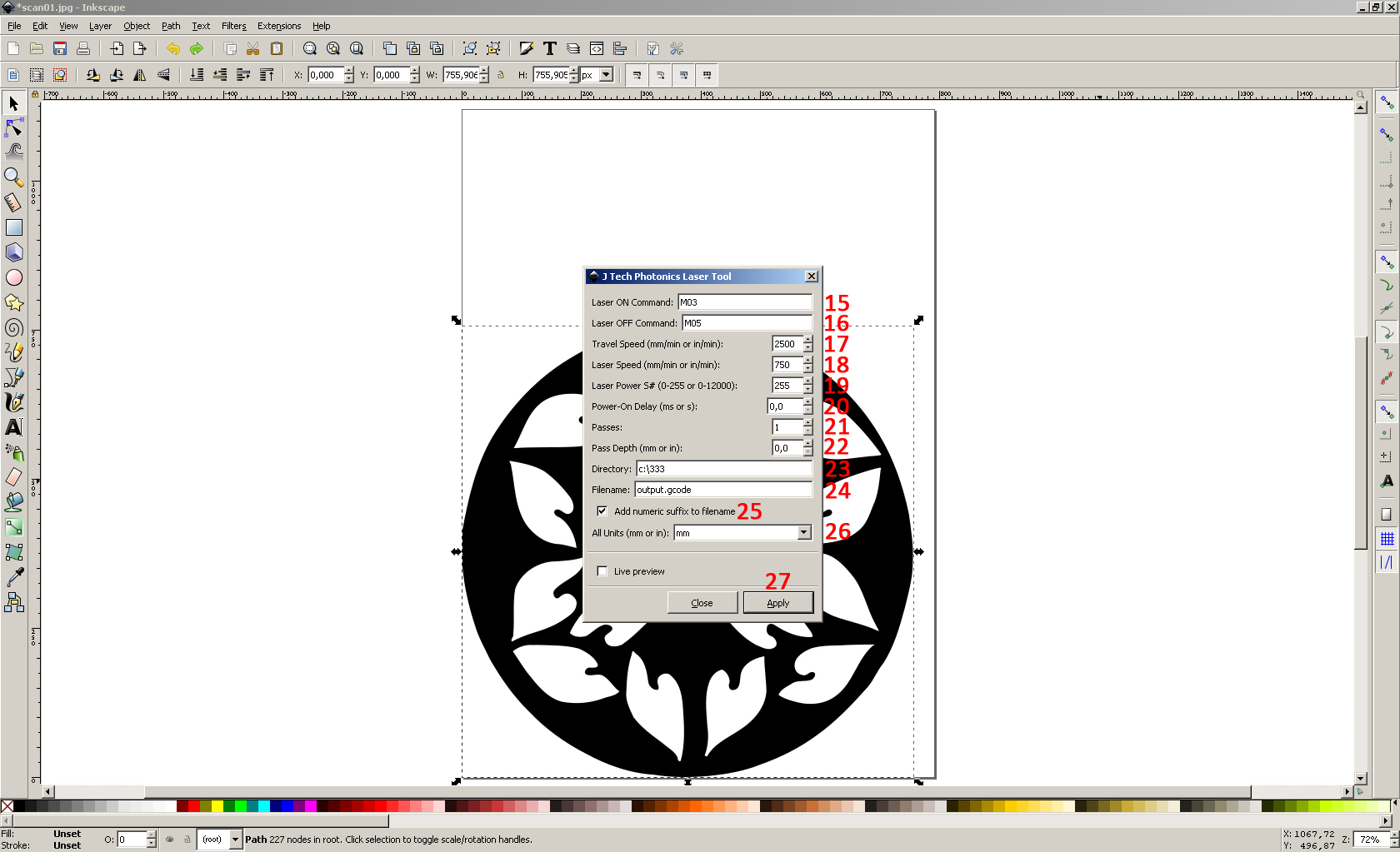

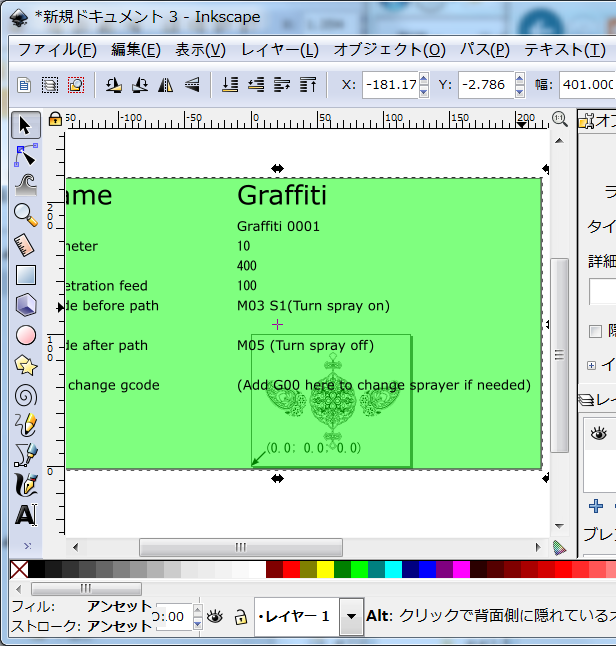

So Gcodetools is a CAM extension which allows to export curves from Inkscape to G-code.īoth Inkscape and Gcode are free (they are licensed under GNU GPL) and cross-platform (they work on Windows, Linux and probably MacOS). (New features from previous version are marked with green) Here is the feature list of Gcodetools 1.6: Inkscape gcode free# Using circular (biarc approximation) or straight line interpolation.Export to Gcode for plotter with tangential knife.Select and remove small paths (area artefacts).Round floating point values to specified precision.You can create custom post-processor by writing down the commands or choose from the list of default post-processors.Apply transforms according to arbitrary points.Tools can be managed by Inkscape's standard procedures (copy, delete, assigned to different layer).Defining different tool's parameters (diameter, feed, depth step, penetration feed, personal Gcode before/after each path, cutters shape, personal tool's changing Gcode).Building trajectory according to the cutter's shape.Two different computation functions for fine cut.Numeric suffix is added to generated files to avoid overwriting.Export Gcode in parametric of flat form.Automatic path subdivision to reach defined tolerance. PS We need more photos of work made using Gcodetools if you can do it I'll be glad to publish it. Unfortunately I can not do it myself because my hobby cnc is not finished yet.

#INKSCAPE GCODE TOOLS DOWNLOAD#

You can freely download Gcodetools from here: Here are some screenshots and made things. Last edited by Lee Roberts 24-08-2010 at 02:03 PM.In today’s industrially developed society, CNC router machine has been widely used in many fields. With the increase in the scope and frequency of use, CNC machine has gradually developed a universal computer language: It is the G Code.

#INKSCAPE GCODE TOOLS CODE#

G code (G-code, also known as RS-274) is the most widely used numerical control (numerical control) programming language.īecause every paragraph in this language starts with a letter G, So we generally call it G code.G code is a numerical control programming language developed by the Massachusetts Institute of Technology in the late 1950s. After a period of development, the Electronic Industry Alliance formulated the earliest G-code standard version in the early 1960s (which is what we know Rs-274). Now, after decades of stable development, G code and its extended languages have been widely used in the manufacturing industry. The CNC G code is mainly used in computer-aided manufacturing to control automatic machine tools.

G code is sometimes called G programming language.

G-code is the generic industry term for the computer language that most CNC machines use to control their movements and how they make parts.The G code is a instruction in CNC programs,It can control CNC Router machine or CNC Laser machine to realize various functions.Such as fast positioning, reverse circular interpolation, forward circular interpolation, intermediate point circular interpolation, radius programming, jump processing and so on.īecause G code needs to be programmed by G code to control the machine to complete various functions.Now,There are two main ways to complete CNC programming.1. Write G code directly for programming, 2.

0 kommentar(er)

0 kommentar(er)